Why JC Metalworks?

JC Metalworks as a precision sheet metal subcontractor was formed in 1986 by Jack Chauhan.

The company was built on four main principles – maintained to this day.

These principles make up a culture that is reflected throughout all areas of the manufacturing services undertaken by JC Metalworks. We are proud of our reputation for quality manufacture of sheet metal products for a variety of industries.

30 years’ experience

End-to-end service

Engineer or Reverse Engineer

Technical Experts

Precision in Product Design, Engineering and Manufacture

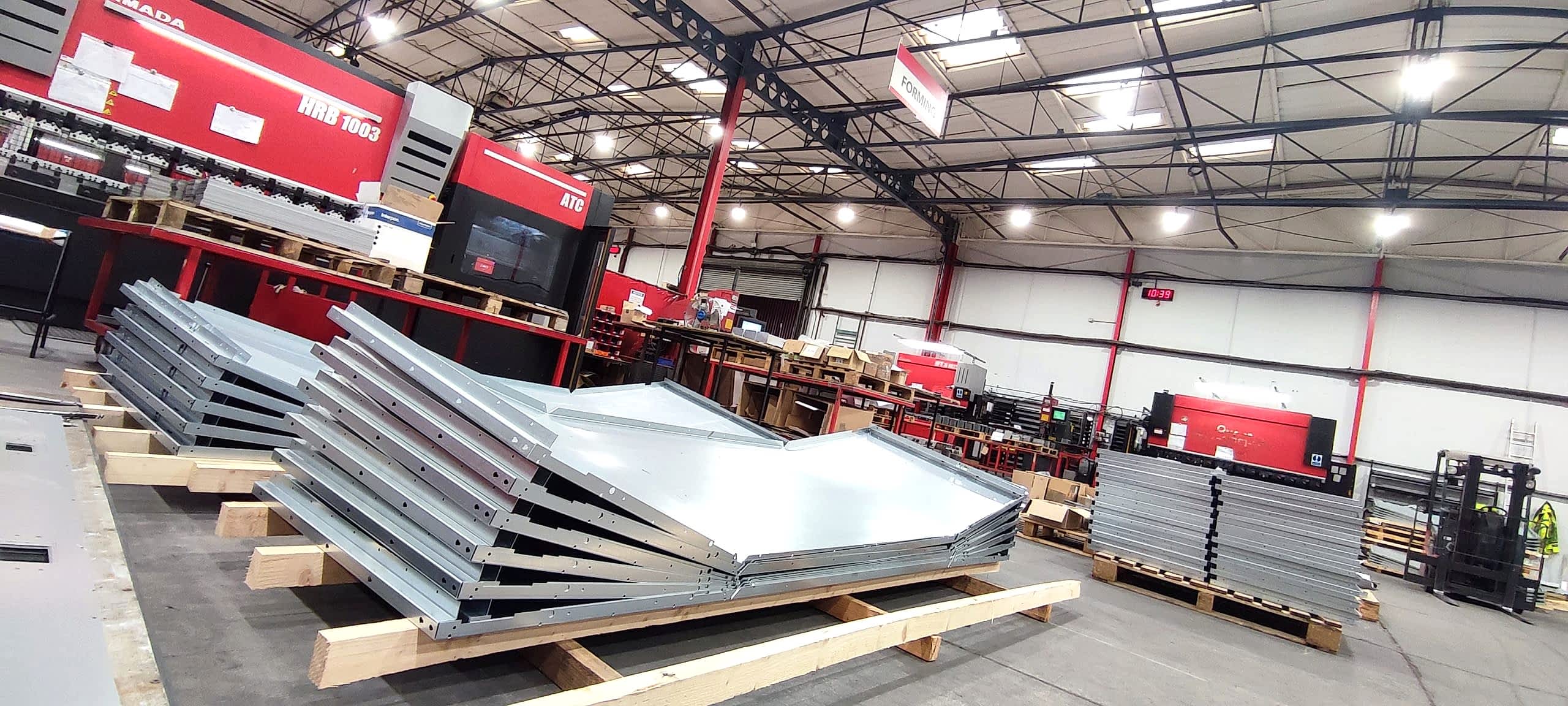

From precision engineering through to final assembly, our team of precision metal manufacturers can assemble a complete final product. This includes electrical work, fitting of non-metal elements (such as wood, graphics, glass etc.), or the assembly of various sheet metal elements.

Our team will arrange packaging and palletise all units for delivery to the client. This process enables us to save on time and cost, as our in-house team will manage the whole precision metal manufacturing process, cutting out much of the co-ordination and planning work for our clients.

Investment in Staff, Equipment and Processes

We are proud of our reputation for developing the skills of our employees and ensuring that all of the production services offered by us are carried out using the best precision manufacturing processes and equipment available to us.

This ensures that our clients receive the best service from our team, and all metalworking products that leave our facility are manufactured to the highest standard, therefore adding value for our clients.

Highly important to our team of precision metal manufacturers here in the UK is the commitment to building long-term partnerships with customers based on delivering high-quality products, adding value to projects, and exceeding expectations. Our employees work hard to understand and deliver what matters most to our clients – only then can we be truly confident that clients will become delighted partners.